Studie: 2005

Purchaser: Severočeské doly – Doly Bílina

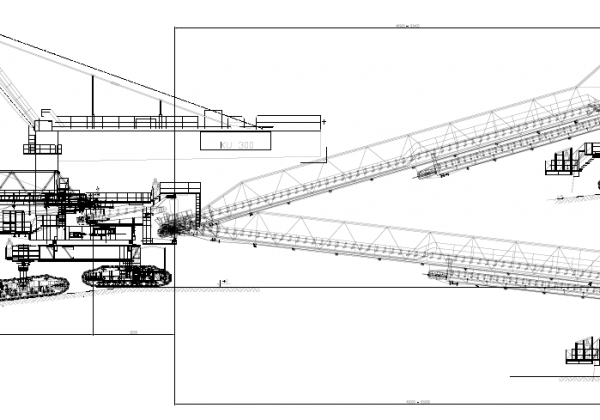

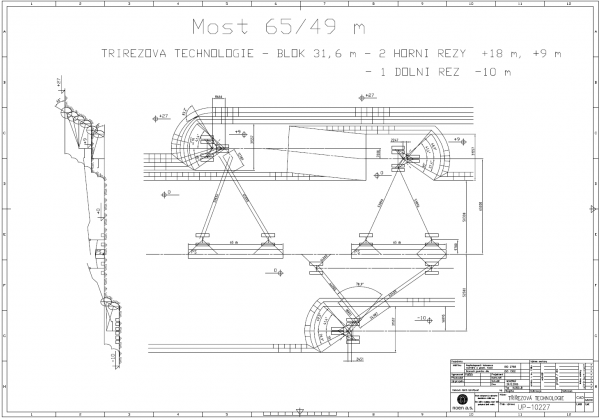

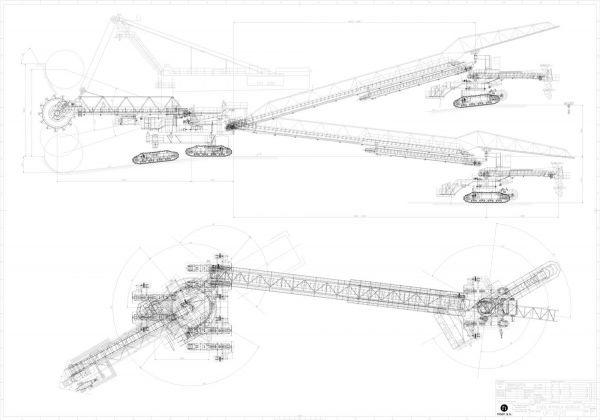

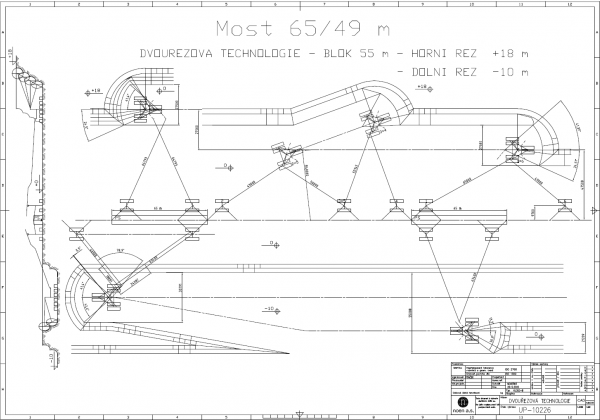

Based on the requirement of Severočeské doly a.s., NOEN, a.s. drew up the KU300 bucket wheel excavator reconstruction study aimed at modernization, an increase in reliability, and time utilization during mining procedures. The basic concept of the KU300 bucket wheel excavator reconstruction involved replacement of the extensible bucket wheel boom with a non-extensible type and replacement of the suspended loading boom with a newly designed loading boom. The maximum impact on technical parameters resulted from requirements for the driving station dead space length of 65 m, the possibility of mining in two blocks with one position of the belt conveyor DPD with total width of 55 m and deep cut of 10 m.

Main parameters

| Parameter | Value | Unit |

|---|---|---|

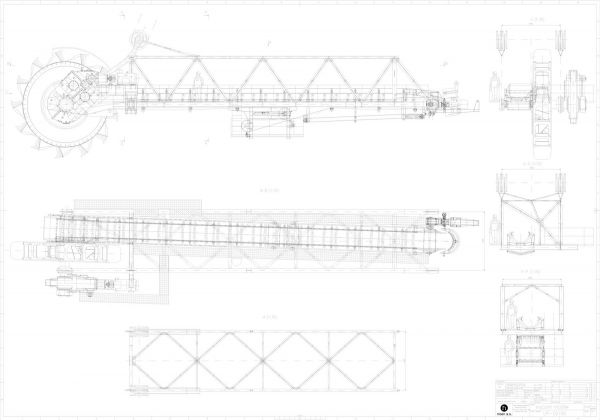

| Lining of bucket wheel from excavator axis (horizontally) | 26 | m |

| Bucket wheel diameter | 7.5 | m |

| Number of buckets | 13 | |

| Installed power of bucket wheel drive | 500 | kW |

| Nominal speed of bucket wheel – 1st speed | 7.16 | 1/min |

| – 2nd speed | 8.16 | 1/min |

| Range of bucket wheel speed control | 50÷120 | % |

| Width of conveyor belt | 1,400 | mm |

| Belt speed | 4.1 | m/s |

| Adjusted longitudinal slope of excavator | 1 : 9 | |

| Adjusted longitudinal slope of supporting car | 1 : 9 | |

| Permissible general tilt of excavator and supporting car | 1 : 20 | |

| Length of connecting bridge | 65 | m |

| Length of connecting bridge retraction | 16 | m |

| Length of discharge boom | 14 | m |

| Slewing range of superstructure related to transfer boom | ± 100 | º |

| Slewing range of connecting bridge related to transfer boom | ± 90 | º |

| Slewing range of connecting bridge related to supporting car | ± 90 | º |

| Width of block (in two advances) | 55 | m |

| Height of the 1st high cut | 18 | m |

| the 2nd high cut | 9 | m |

| low cut | 10 | m |