Conveying capacity: 300 m3/h (800t/h)

Material to be loaded: železná ruda (2,7t/m3)

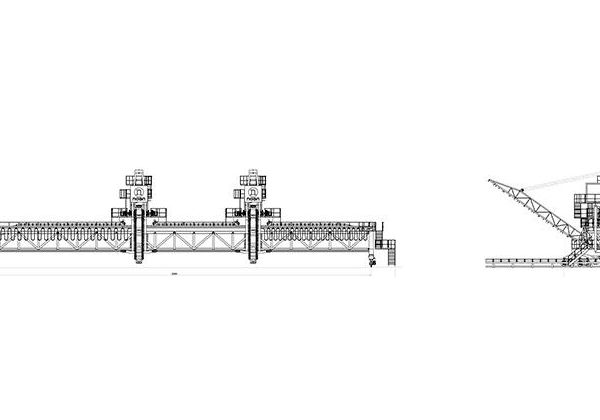

Length/width: 20 m / 62 m

Height: 13 m

Weight: 370 t

Installed power: 400 kW

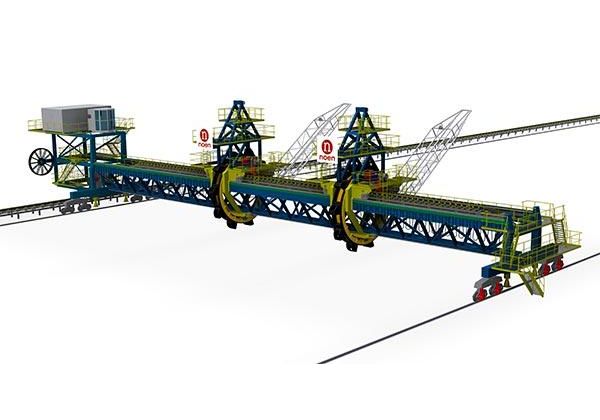

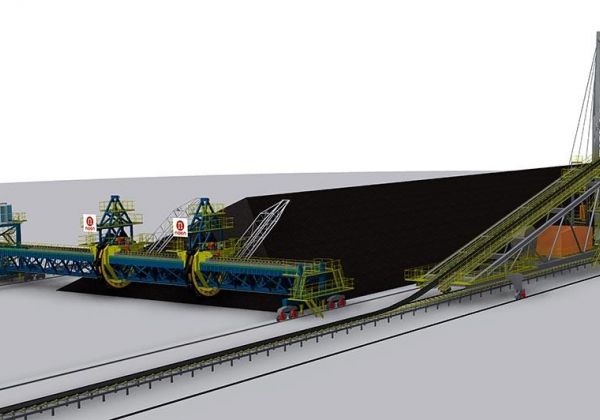

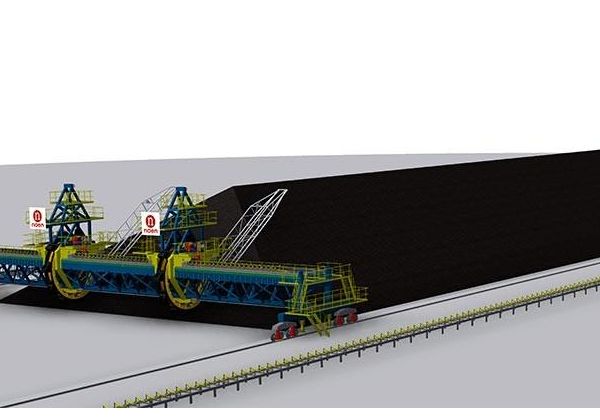

The bridge reclaimer MN 3.0-50 is used for stockyard redumping of crushed iron ore or other bulk materials as well. The reclaimer consists of the bridge structure mounted on a rail undercarriage. The belt conveyor is placed over the total length of the bridge and conveys redumped material from two* bucket wheel carriages to the central outgoing conveyor positioned along the stockyard. Each bucket wheel carriage is mounted on a rail undercarriage and travels in the direction of the bridge longitudinal axis above the belt conveyor. The bucket wheel carriage above all consists of a steel frame, a rail undercarriage, the bucket wheel itself, and a breaker.

* bridge reclaimer can be equipped with only one bucket wheel carriage

– the bucket wheel carriage travel along the bridge is realized by means of an electromechanical drive, same as that for the breaker lift.

– the reclaimer travel along the stockyard is realized by means of electromechanical drives directly mounted on travelling wheel shafts.

The reclaimer is placed on the rail undercarriage. Length of travelling track (rails), thereby length of stockyard as well, is only limited by size of a cable drum for power supply of the machine.

Main parameters of machine

| Weight in running order | 370 | t |

| Theoretical conveying capacity of machine | 300 | m3/h |

| Bulk density of material to be stacked | 2.7 | t/m3 |

| Belt width | 1,200 | mm |

| Bridge length | 62 | m |

| Machine height | 13 | m |

| Machine width | 20 | m |

| Rail gauge | 50 | m |

| Travel speed of reclaimer | 4-20 | m/min |

| Installed power in total | 400 | kW |

Dimensions of stockyard

| A – Offset – handling area | communication | 8 | m |

| B – Maximum width of stockyard | 38 | m |

| H – Maximum height of stockyard | 12 | m |