Conveying capacity: 7000 dm3/h

Length/width/height: 175 m/ 22 m / 40 m

Maximum height of stacking: 26 m

Weight: 1600 t

Installed power: 3050 KW

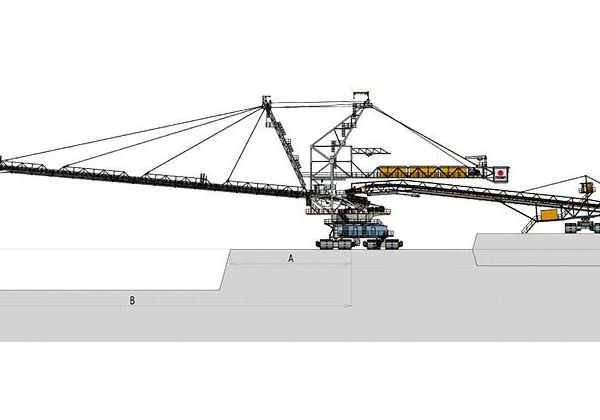

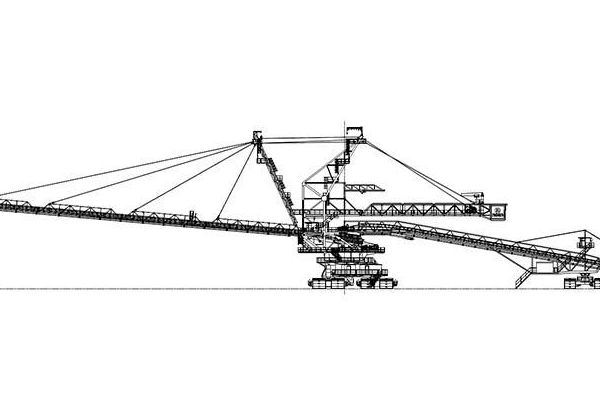

The Z7000-90 stacker is used to stack crushed overburden to a dump.

The stacker consists of a substructure (steel structure connecting three crawler twins of the undercarriage). The slewing superstructure with the tower and the counterweight boom with a counterweight are mounted on the substructure. A discharge boom equipped with a belt conveyor is hinged on the superstructure.

A hinge joint of the connecting bridge is realized at the superstructure level, in suspension of the counterweight boom. This steel structure is supported at another end with a supporting car. The connecting bridge is equipped with a belt conveyor with a charging hopper at the lower end. Material from the preceding technology (e.g. long-distance belt conveyors) is received at this place and further conveyed to a conveyor of the discharge boom. The supporting car consists of a crawler undercarriage, a small substructure and a swivel plate. The connecting bridge is just mounted on this plate.

– The slewing range of the superstructure against the substructure is realized by electromechanical drives.

– Tilting of the discharge boom is realized by means of a hoist and a pair of electromechanical cable winches.

Main parameters of machine

| Weight in running order | 1,600 | t |

| Theoretical conveying capacity of machine | 7,000 | m3 |

| Length of discharge boom * | 90 | m |

| Length of connecting bridge * | 80 | m |

| Slewing range of discharge boom against connecting bridge | +-110 | ° |

| Slewing speed of discharge boom top | 20 | m/min |

| Lifting speed of discharge boom top | 2 | m/min |

| Maximum height of stacking | 26 | m |

| Maximum difference in height of undercarriage positions | +-4 | m |

| Specific pressure on surface for travelling | 77 | MPa |

| Travel speed | 2.5-10 | m/min |

| Ball way diameter | 9.2 | m |

| Installed power in total | 3,050 | kW |

* Distance between slewing axis of the machine superstructure and axis of a reversing drum of the belt conveyor.

| Weight in running order | 15 | m |

| A – Minimum offset ** | 7,000 | m3 |

| B – Maximum distance of stacking | 110 | m |

| H – Reach of discharge boom | 25 | m |

| h – Height of supporting car position level | +-4 | m |

** Depending on base load-bearing capacity